+86 19315524132

+86 755-28452952

saleglobal@sgte.cn

1-3 buildings,No.26 Wanfu Road,Pinghu Village,Pinghu Town,Shenzhen,China

Views: 0 Author: Site Editor Publish Time: 2025-07-28 Origin: Site

Have you ever experienced electronic circuit issues due to noise interference? Common mode chokes play a crucial role in eliminating such interference. However, diagnosing and fixing problems with these components can be tricky.In this post, we'll guide you through the process of identifying and resolving common mode choke issues. You'll learn how to diagnose potential failures and apply effective solutions to ensure smooth circuit performance.

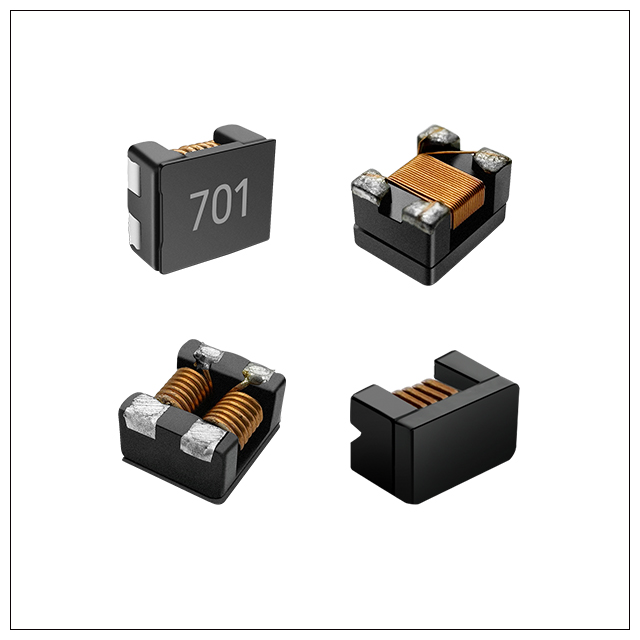

A common mode choke is a passive electrical component designed to reduce unwanted interference in circuits. It consists of two windings wound on a magnetic core. These components are key for filtering electromagnetic interference (EMI) and radio frequency interference (RFI).

Common mode chokes block common-mode signals while allowing differential signals to pass. They’re particularly effective in suppressing noise that appears simultaneously and in-phase on both wires of a circuit. This prevents disruptions caused by unwanted high-frequency signals.

These chokes are essential in power supplies and data lines. In power systems, they ensure stable voltage and reduce noise. In data transmission, they prevent signal distortion caused by external interference.

Without them, noise could compromise the performance of your electronics, making common mode chokes a critical component in most modern devices.

Common mode chokes play a vital role in reducing noise and ensuring the smooth operation of circuits. However, like any electronic component, they can fail over time. Understanding why these failures occur can help you identify and fix issues faster.

Common mode chokes can fail due to several reasons, including poor design, manufacturing defects, or excessive operational stress. Overloading the choke beyond its rated capacity, environmental factors, and age can also lead to failures.

An open circuit occurs when the choke’s winding breaks or becomes disconnected. This stops current flow through the choke, rendering it ineffective in filtering noise.

A short circuit happens when windings or the choke’s core material touch each other or ground, causing a direct path for the current. This disrupts the choke’s function and can lead to overheating.

If the choke’s impedance is not correctly matched with the circuit, it won’t block common-mode signals effectively. This mismatch reduces its ability to filter out noise, compromising circuit performance.

Damage or defects in the core material, such as cracks or material degradation, affect the choke’s magnetic properties. This can lead to reduced inductance, affecting the choke's ability to filter noise properly.

Resonance occurs when the choke’s inductance aligns with the circuit's frequency, causing it to oscillate. This can generate voltage spikes that might damage other components in the circuit.

These common failure types highlight why it’s important to regularly check your common mode chokes for wear and tear. Identifying these issues early can save you time and prevent further damage to your circuit.

Diagnosing issues with common mode chokes can seem daunting, but it’s an essential part of maintaining your circuit's performance. By following systematic diagnostic methods, you can quickly identify common choke failures and address them before they cause significant problems.

Start by visually inspecting the choke. Look for obvious signs of damage such as:

Broken wires

Burned insulation

Loose or corroded connections These issues can indicate potential failure points, which may require repairs or replacement.

Using a multimeter, measure the DC resistance of the choke’s windings. Here's what to check:

Open Circuit: Infinite resistance indicates a broken or disconnected winding.

Short Circuit: Very low resistance suggests a short, possibly due to a wiring issue or internal damage.

Utilize an LCR meter to measure the choke’s inductance. Compare the measured value to the specifications of the component. A deviation could mean:

Incorrect inductance: The choke may not be able to filter noise effectively.

Degraded performance: Damaged core materials could affect the choke’s inductance.

Measure the choke’s impedance at various frequencies using an impedance analyzer. This test helps you determine:

How well the choke blocks common-mode signals.

Whether there’s an impedance mismatch that reduces the choke’s filtering capability.

Use an oscilloscope to monitor the voltage across the choke. Watch for:

Voltage spikes or oscillations that could indicate resonance or improper choke operation. These spikes could point to underlying resonance issues, which can damage components over time.

Overheating can be a sign of problems like excessive current flow or poor design. During operation, feel the choke’s temperature or use a thermal sensor. If it’s unusually hot, it might be:

Overloaded: The choke is handling more current than it’s rated for.

Poor heat dissipation: Insufficient airflow or heat sink could be causing overheating.

By following these diagnostic steps, you can quickly identify whether your common mode choke is operating correctly or needs attention. A thorough check of each step helps ensure reliable performance and reduces the risk of failure.

Fixing common mode choke issues is essential to maintaining your circuit's efficiency. The right approach depends on the specific problem you're facing, but here are some methods for resolving common issues.

If your common mode choke has an open circuit or short circuit, it’s often best to replace it. When the choke’s windings are damaged beyond repair, a replacement ensures your circuit runs smoothly without noise interference. Replacing it is necessary when:

The damage is too severe to rewind.

The choke no longer meets the required specifications.

If the core material is still intact and the damage is limited to the windings, rewinding the choke can be an effective solution. Here's how:

Carefully remove the damaged winding.

Use the proper wire gauge and number of turns.

Ensure the winding direction matches the original configuration.

To fix impedance mismatch issues, either adjust your circuit or select a new choke. Here’s what to do:

Adjust the Circuit: Change the impedance of surrounding components to match the choke’s impedance.

Select a New Choke: Choose a choke with the correct inductance and impedance ratings for your application. This ensures the choke can effectively filter common-mode signals.

If the core material is defective or has lost its magnetic properties, it’s time to replace it. Using the right core material can prevent further issues and improve the choke’s performance. Consider switching to a material with better magnetic properties, such as a higher-grade ferrite core.

Resonance problems arise when the choke's inductance coincides with the circuit’s resonant frequency. To solve this, adjust the capacitance or inductance of the circuit to shift the resonant frequency away from the choke’s operating range. This prevents voltage spikes that can damage the choke and other components.

Overheating can lead to common mode choke failure. To address this:

Add Heat Sinks: Attach heat sinks to the choke to improve heat dissipation.

Improve Airflow: Enhance airflow around the choke by adding fans or redesigning the circuit to ensure adequate cooling.

By following these steps, you can resolve many of the common issues with your common mode choke and keep your circuits running efficiently.

Selecting the right common mode choke and properly testing it is key to ensuring your circuit runs smoothly. Incorrect choices can lead to noise issues, poor performance, and even damage to other components. Let’s dive into why this is so important.

When choosing a common mode choke, consider these key factors:

Inductance: The choke’s inductance must match the circuit’s requirements for effective noise filtering.

Impedance: Choose a choke with the correct impedance to block common-mode signals without affecting differential signals.

Current Rating: The choke should handle the maximum current of the circuit without overheating or degrading.

Application Needs: Ensure the choke is designed for your specific application, whether it’s power supply filtering, data transmission, or EMI reduction.

Testing before and after installation is crucial for verifying the choke’s performance:

Pre-Installation Testing: Check the choke's inductance, impedance, and resistance before installation to ensure it meets specifications.

Post-Installation Testing: Once installed, verify the choke’s performance in the circuit. Use tools like an oscilloscope to check for effective noise filtering and impedance matching.

Proper integration of the common mode choke is essential for its effectiveness. Make sure to:

Place it correctly: Position the choke in the right part of the circuit to maximize noise reduction.

Integrate it well: Ensure the choke is properly connected, and its impedance matches the surrounding components for optimal performance.

By selecting the right choke, testing it thoroughly, and integrating it properly, you can ensure your circuit performs efficiently and with minimal noise.

To avoid future problems with common mode chokes, it's essential to take a proactive approach. Regular maintenance, quality components, and proper care can extend the life of your chokes and prevent unnecessary failures.

Regular Inspections and Testing

Make it a habit to inspect your common mode chokes regularly. Look for signs of wear, damage, or overheating. Use a multimeter and oscilloscope to check performance at regular intervals. Catching issues early can save you time and prevent more serious damage down the line.

Use High-Quality Components

Always choose high-quality chokes designed for your specific application. Quality components tend to last longer and perform better under stress. When selecting a choke, focus on the manufacturer’s specifications and reputation. A well-built choke reduces the likelihood of failures, ensuring smoother circuit operation over time.

By following these simple practices, you can prevent common mode choke issues and enhance the longevity of your circuits.

Diagnosing and fixing common mode choke issues is crucial for maintaining circuit performance. Regular inspections and proper testing can help identify and resolve problems early. A well-functioning choke ensures effective noise reduction and reliable operation.

Remember to regularly test and replace common mode chokes as part of your circuit maintenance to prevent future issues.

A: A common mode choke filters out electromagnetic interference (EMI) and radio frequency interference (RFI), particularly in power and data lines.

A: Signs of failure include visual damage, unusual resistance readings, improper inductance, and overheating.

A: Yes, you can replace or rewind a choke if damage is limited. Severe damage, however, requires replacement.

A: Resonance creates voltage spikes, potentially damaging the choke or other components. Adjusting the circuit’s frequency helps prevent this.